The Church Clock

Its history and its workings 2006

|

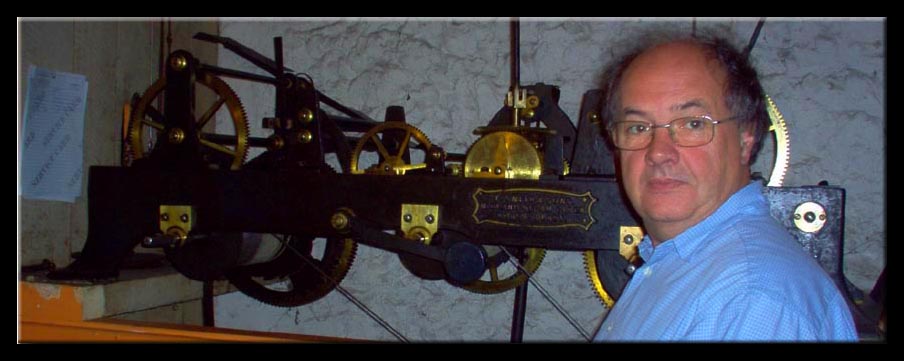

Peter Cook about to

present an insight into the workings of this wonderful old clock

Photo

Dawn Tonge

|

|

M |

This

is a familiar friend to all of us and is normally the only part of

the Church clock we get to see. |

Over

to Peter |

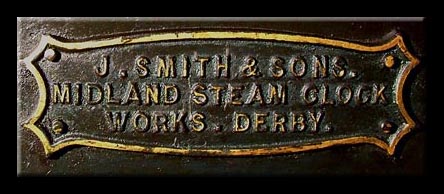

| The

clock, complete with a new dial and hands, was donated by Mrs King

Smith as part of the general refurbishment of the church that took

place at the end of the 19th Century. The cost to Mrs King Smith

- (£200 or £14,500.00 in today's money) - and the fact

that the clock was officially started on Christmas Eve 1889, seems

to indicate that it replaced an earlier one, the only evidence for

which is a picture of the church dated 1870 showing a Diamond shaped

dial and probably a single (hour) hand. |

The

clock is a horizontal frame three-train tower clock, and was manufactured

by John Smith & Sons at the Midland Steam Clock works in Derby

in 1889. Steam Clock Factories, were so called because they had steam

engines to power the machinery. Smiths installed the clock in the

ringing chamber, and still make an annual visit to maintain the mechanism.

Lord Grimethorpe invented the horizontal frame design in 1854 for the Great Clock at Westminster, more commonly known as Big Ben after the name of its largest bell. |

m |  |

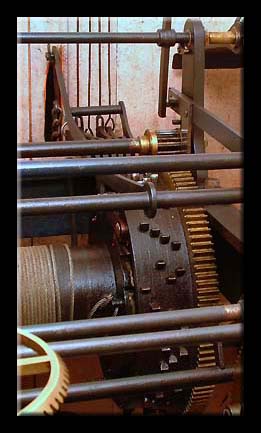

The

design’s main advantage is that all the wheel bearings are bolted

onto a horizontal frame, making the clock movement easier to manufacture,

assemble on site and to service. The cast iron frame is 4 ft 6 in

(1.4 m) long, and has three separate trains of wheels. As is traditional

in almost all chiming clocks, the central train tells the time and

drives the hands. The right hand train strikes the hours while the

left hand train plays the chimes each quarter of an hour. |

|

The pendulum, which beats

3150 times each hour or 52.5 times per minute, is about 5 ft (1.5

m) long. The bob is a rounded end cast iron cylinder 6" (15 cm)

diameter and 15" (38 cm) long. It weighs approximately 90 lbs

(42 kg) and is suspended on a hollow wooden rod. The time train has a pinwheel escapement in which each swing of the pendulum allows one pin on the escape wheel to work its way down through two “steps” attached to a crutch, which is swung by the pendulum rod. This is a much simpler, and cheaper, escapement than the gravity escapement also developed by Lord Grimethorpe for the Westminster clock. |

|

M |

|

|

M |

|

Three

weights drive the clock one for each train. All three are located

to the right hand side of the clock and the cables run from the clock

up to pulleys at the top of the tower some 36 ft (11 m) above the

clock - and directly over the seat on which the vicar sits during

services. The heaviest weight drives the chimes. This is 3.75 cwt

(190 kg). The strike is driven by 2.25 cwt (115 kg) while the time

train has a very small 0.5 cwt (25 kg) weight. When fully wound the small time weight can keep the clock ticking for a full week. Unfortunately (for the clock winder) the chime and strike weights will only do their job for half that time before needing to be wound back up to the top of the tower. This means that the clock has to be wound twice each week. As Ken has already mentioned, the clock winder for 33 years was Doug Vellender who was also captain of the bell ringers; so winding was done on Sunday morning before bell ringing for the 9:00 am service and on Wednesday evening before ringing practice. This is still the pattern even though Doug has now retired. The clock is wound with a large crank handle on three winding squares across the front of the clock. The central square, for the time train, has a small weighted lever in front of it that needs to be lifted to gain access for winding. This is a form, of what is known as "bolt and shutter" maintaining power which keeps the clock ticking while the weight is wound up. The larger weights are suspended on a three-wire compound pulley system. This reduces the load for winding, but even with the leverage afforded by the crank handle the chime train needs a 22 lb (10 kg) pull, and forty two turns of the handle each wind. The total energy used by the clock in a week is the equivalent of lifting a 1 ton weight about 23 ft (7 m). The original clock would have been set to local mean time (about 5 minutes and 55 seconds behind Greenwich) taken from a sundial; possibly the one that can be seen set in the wall on the south side of the church. However by 1880, nine years before the clock was installed, Greenwich Mean Time had been adopted (in law) as the time standard for the whole country; a trend begun in 1840 by the Great Western Railway, which ran through Newbury. Today the clock is set by reference to a radio controlled clock kept in the ringing chamber and synchronized to the national atomic clocks. |

|

|

Research

and photos by Peter Cook

|

|

|

Photo

Ken Tarbox

|

Photos

: Peter Cook : Dawn Tonge : Ken Tarbox

Main Site Menu : 2006 Archives Menu : Gift Weekend Menu

.